ISOWA offers customised solutions

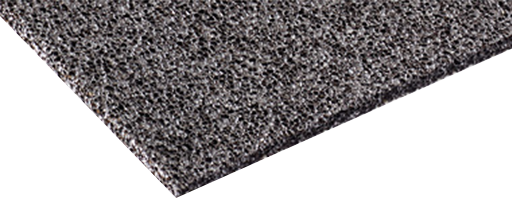

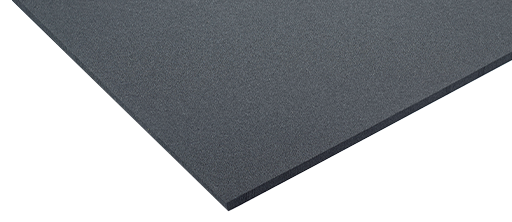

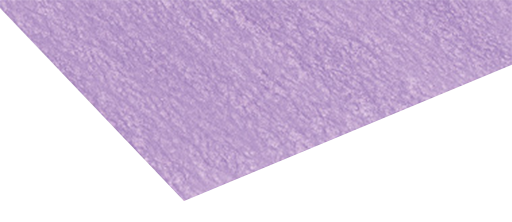

Motor vehicles that no longer have combustion engines can be quite noisy for occupants. ISOWA offers [E]special foams and tapes designed to adress both airborne and structure-borne noise, depending on the source. Our silicone and PUR elastomer specialists help to reduce vibration noise and decouple sound sources. While thin foils are used as separators, high-performance tapes ensure a permanent bond.

Ready-made solutions are rare, we find the better solution together.

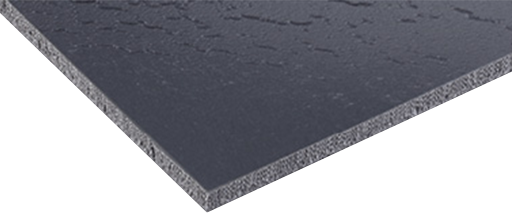

![silent[fit]® 1 – silent[fit]<sup>®</sup>1](https://emobility.isowa.de/medien/produkte/xisowa_34041.png.pagespeed.ic.o_gI1WyyLV.png)

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

show details

Details

TecSa - Technical cleanliness based on VDA 19 or ISO 16232:2018

Component cleanliness is defined as the absence of particles on components that could impair or prevent the further production process or the correct functioning of the component or assembly. The solution to specific cleanliness testing or production issues is therefore always the task of component or product-specific specialists. When a component is considered clean enough can only be determined on an application-specific basis. This is because the limit value definition for component cleanliness is intended to ensure the component function and must already be determined during the development phase of the component.

ISOWA supplies cleanliness-compliant products that are tested and coordinated with your project-specific requirements in the areas of high-voltage, sensor technology or electronics as part of the manufacturability analyses and advance quality planning.

We cooperate with accredited testing laboratories to carry out residual dirt analyses and are continuously expanding our capabilities with regard to environmental cleanliness in production and logistics as well as cleanliness-compliant manufacturing processes.

Definition in your requirement

Determination of the function

Determination of continuous and extreme load

Selection of the most suitable material

Optimisation in terms of shape & mass

Determination of the design

Selection of the most suitable manufacturing process

Suggestion of the better solution

Our aim is to offer more than just a product - we offer solutions. With our think tank, we turn your visions into reality and optimise your production processes. Discover the difference that real innovation can make to your value chain.

Self-adhesive seals for enclosure doors.

Valve insulation for heating and cooling applications

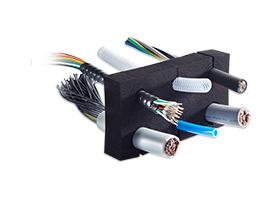

Individual solutions for wall ducts.

Vibration isolation for demanding tasks.

Insulating shells for your products.

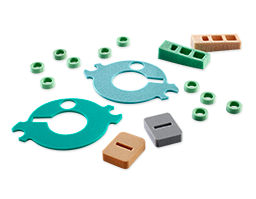

Seals for attachments.

Encapsulating disturbing noises.

Well proven and effective noise reduction.